"Jeremy Bloyd-Peshkin" (ulteriormotors)

"Jeremy Bloyd-Peshkin" (ulteriormotors)

09/12/2013 at 15:15 • Filed to: Adventures in German Engineering

4

4

12

12

"Jeremy Bloyd-Peshkin" (ulteriormotors)

"Jeremy Bloyd-Peshkin" (ulteriormotors)

09/12/2013 at 15:15 • Filed to: Adventures in German Engineering |  4 4

|  12 12 |

It's been a while since I last posted about Oliver, my 1987 BMW 535i. Since my last update, I've gotten some minor work done (changing fluids, tightening suspension components, hunting down rattles, etc), but there's been one major nagging problem. My driveshaft is clunky. It also vibrates at high speed because it isn't balanced, but the more pressing issue is the rattle. I would hear it every time I slowed to a stop. Clunka clunka clunk. It wasn't fun, as I don't particularly enjoy living in constant fear of catastrophic drivetrain failure, and I didn't even know what was wrong. So one evening I pulled the car into the garage, jacked it up, and after narrowly escaping burning myself on the exhaust, started poking around the driveshaft. The center support bearing was a bit worn, but still perfectly serviceable, making the only other probable culprit the universal joint. And sure enough, the u-joint had about 1/8" of play in both directions. The universal joint had been rebuilt once before, and horribly mistreated since. I guess it was just time. Fortunately for me, rebuild kits for 5-series universal joints are readily available and not very expensive. I ordered one, and waited.

The day finally arrived to rebuild it. It was a cell-phone camera kind of day, so I'm sorry about the picture quality. But here we go.

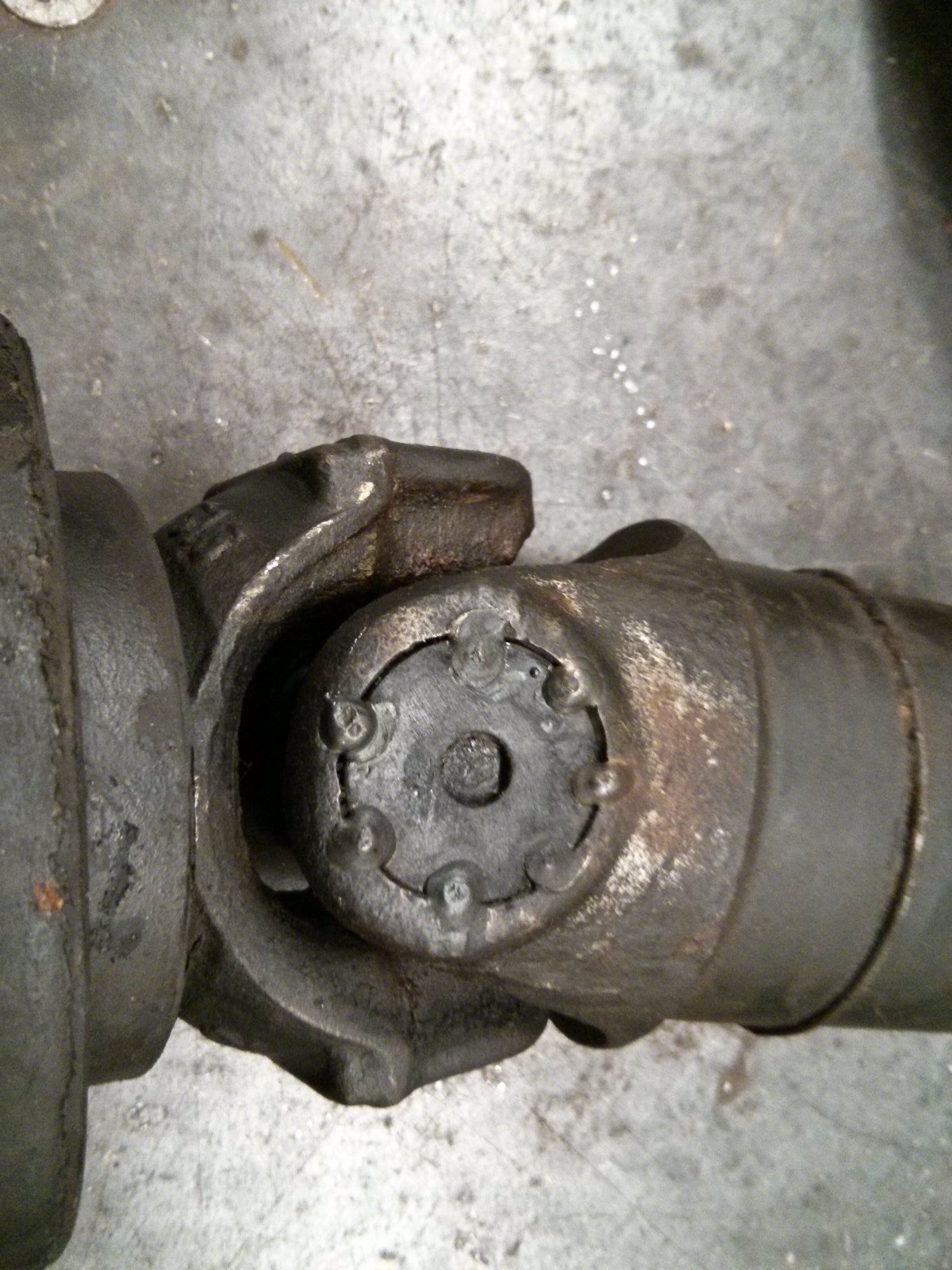

This is the trouble joint. You can see some tack welds on it. I'll get to those later. But first I had to remove the driveshaft.

Here's the front of the driveshaft, where it mates with the transmission. You'll notice there's a missing bolt. I didn't remove that, it was just gone. That probably wasn't helping the vibration, but it made removing everything easier. It also helps with weight reduction. Every ounce counts!

I had the back wheels jacked up by the diff. It's a two-person job loosening all the bolts. One person rotates the driveshaft so reach the bolts, then the other one stands on the brakes so the bolts can be broken loose. Rinse and repeat, then set the car back down.

Here's the driveshaft, in full potato quality. See the rust on the left side? The rear half of the driveshaft is actually from a 3-series, and was cut and welded to fit the 5-series. That's where the imbalance came from. Anyhow, back to the universal joint.

I said I'd talk about the tack welds. The BMW driveshafts didn't retain the yoke in the universal joints with circlips, they were staked in. So the last time this was rebuilt, the only way the yoke could be retained was by welding in some washers. They held, but were a pain to get back out. I started by trying to grind out the tacks, but ran out of patience.

And so driveshaft repair time overlapped with fuck this shit o'clock, and I put eh driveshaft in the mill and milled out the washers. There aren't many problems that liberal application of carbide can't solve.

It did less damage than a grinding wheel.

I pressed out the old yoke, bearings, and center support. The yoke had plenty of wear, and the bearings were pretty bad. The center support was fine, but I decided to replace it anyway.

Here's the new yoke with new bearings, because shiny.

Very carefully, I pressed the yoke back into the driveshaft.

And then I completed the repair by welding in new washers, because I hate my future self who has to rebuild this again. I reassembled the driveshaft, and I installed it in the car (with three bolts in the front this time!), and then took it for a test drive. There's no play now, and it doesn't clatter and clunk. The vibration is better as well, making driving more comfortable. So that's another repair off the list. At some point in the future I'm going to have to replace a front lower control arm, but I'm putting that one off because I hate dealing with dampers. The real test will be a trial by fire this weekend at an autocross. We'll see how everything holds up.

Until next time, I'll be sticking it to the man by parking my BMW squarely in its parking space. Happy repairs!

Party-vi

> Jeremy Bloyd-Peshkin

Party-vi

> Jeremy Bloyd-Peshkin

09/12/2013 at 15:19 |

|

Many times I have been in the garage until fuck this shit o'clock. Good to see people still work on their cars.

vdub_nut: scooter snob

> Jeremy Bloyd-Peshkin

vdub_nut: scooter snob

> Jeremy Bloyd-Peshkin

09/12/2013 at 15:43 |

|

Are you by any chance a Kettering student? I know of a(nother?)bimm named Oliver that's made its rounds up there.

Jeremy Bloyd-Peshkin

> vdub_nut: scooter snob

Jeremy Bloyd-Peshkin

> vdub_nut: scooter snob

09/12/2013 at 16:02 |

|

No, that Oliver is a 3-series with an m30 swap. Mine is more sedate.

Z_Stig

> Jeremy Bloyd-Peshkin

Z_Stig

> Jeremy Bloyd-Peshkin

09/12/2013 at 16:17 |

|

It's a real treat when you find ghetto repairs on your finely engineered German automobile!

ZeroOrDie - Powered By MZR

> Jeremy Bloyd-Peshkin

ZeroOrDie - Powered By MZR

> Jeremy Bloyd-Peshkin

09/12/2013 at 16:39 |

|

One more thing off a long list I am sure. Keep chipping away!

ASheep

> Party-vi

ASheep

> Party-vi

09/12/2013 at 17:26 |

|

I find that if I'm still doing really important/delicate things at fuck-this-shit-o'clock, I'm probably going to turn it into fuck-shit-up-oh-cock... And that never ends well.

Jeremy Bloyd-Peshkin

> Z_Stig

Jeremy Bloyd-Peshkin

> Z_Stig

09/12/2013 at 17:49 |

|

Ghetto repairs are one thing. Ghetto repairs on my car are another. For example, the original universal joint was staked together. You weren't supposed to rebuild it, you were supposed to get a new one. A rebuild kit is ~$20. A new driveshaft is ~$1000. The choice is obvious. And besides, it really only looks ghetto. It's rock solid, and won't ever go anywhere.

vdub_nut: scooter snob

> Jeremy Bloyd-Peshkin

vdub_nut: scooter snob

> Jeremy Bloyd-Peshkin

09/13/2013 at 13:59 |

|

Since you know of it, I assume you've seen it? I love that car. So many stories.

Jeremy Bloyd-Peshkin

> vdub_nut: scooter snob

Jeremy Bloyd-Peshkin

> vdub_nut: scooter snob

09/13/2013 at 14:18 |

|

Oh hell yeah. So much fun, so much fear, so much love.

Axel-Ripper

> vdub_nut: scooter snob

Axel-Ripper

> vdub_nut: scooter snob

09/19/2013 at 17:00 |

|

You'd also be somewhat familiar with THIS Oliver......

vdub_nut: scooter snob

> Axel-Ripper

vdub_nut: scooter snob

> Axel-Ripper

09/20/2013 at 11:46 |

|

This wasn't your car, was it?

Axel-Ripper

> vdub_nut: scooter snob

Axel-Ripper

> vdub_nut: scooter snob

09/20/2013 at 12:12 |

|

Yes, yes it was.